Proud to work in a department that doesn't exist anywhere else in the world

As our Manager Production Cuttings, Jan Arends is responsible for producing young plants from cuttings. He has been with Florensis for 10 years and recently switched to our new production location in Dinteloord, the Netherlands.

What are the sticking robots used for in the production of lavender starting material?

After arriving from our production location in Ethiopia, the lavender cuttings are first inspected by Naktuinbouw, the Dutch horticultural inspection service. Then they are checked internally to make sure they comply with our quality standards and the profile we adhere to at Florensis. After that, the cuttings go to the Mechanical Sticking department, where 24 robots stick them day and night, seven days a week. This is done using Artificial Intelligence software which has been trained over many years to recognise cuttings and process them in the correct way.

How does the customer benefit from the use of robots at Florensis?

Using robots enables us to process lavender cuttings and get them to the rooting department within a few hours of their arrival from Ethiopia. This is a much shorter turnaround time than we could offer before we had the robots, thanks to 24-hour processing. In addition, the room where the robots work is air-conditioned and has carefully controlled relative humidity. We have full control over the climate there, specifically tailored to unrooted cuttings.

How far have we got in developing our robots compared with our competitors?

With the software we use and the scale of our operations, we are absolute front runners in the use of sticking robots. We have a clear lead because we were one of the first companies to develop these robots and use them widely.

How does your team like working with these innovative self-learning robots?

Our "robot team" is growing every month. We now have a club of 18 enthusiastic employees who enjoy rising to the challenge of clocking up top performance together with their "robot colleagues". They are proud to work in a department that doesn't exist anywhere else in the world and is committed to improving, growing and learning from each other every day.

"Short turnaround time thanks to 24-hour processing" - Jan Arends

How do the robots speed up the production process?

The capacity of the robots is high: they process around 2,000 cuttings per hour, 24 hours a day. That's an enormous step forward in terms of the throughput rate and is having a positive impact on our end product. With 100% uniform cuttings arriving from our mother plant location in Ethiopia, we are able to stick millions of cuttings per week. And all in the same way, at the same depth and height, and accurate down to the last millimetre!

Which departments benefit from the robots?

Because robots are so incredibly reliable, they never get sick, their advantages also filter through to other departments, such as transport planning from Ethiopia to our production location in Dinteloord. This reliability is an advantage for our Logistics Department as it ensures predictability and the work is spread out by the 24-hour operations. This reliability is also a big advantage for the Cultivation department, because unlike humans, robots stick each cutting in exactly the same way. And we humans can always make adjustments if necessary.

Latest news

Visit our Spring Show 2024

After 2 years of development, we proudly present our latest value-added products within the market for biennials and spring-flowering perennials.

Read more

Helleborus Advent Star Event

Along with our top 10 Helleborus customers, we set up a trial to gain even more insight into the qualities of our Advent Star.

Read more

These Retail Solutions will help you take the next step in a sustainable assortment.

As growers and retailers, your want to offer customers gardening solutions that are both convenient and ecologically conscious.

Read more

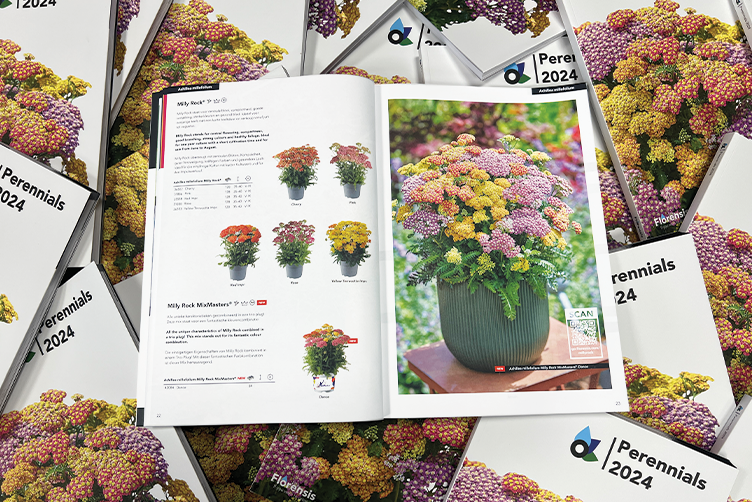

Check the Retail Solutions in our new Perennials Catalogue.

As with the Annuals catalogue, we thought about the environment with the Perennials catalogue by reducing the number of pages.

Read more

Why certifications and CO2 calculations can benefit you

As a customer, you want to know where your plants come from and how they are grown. Hans Goudswaard, responsible for Quality Assurance, considers transparency very important.

Read more

Sustainability under the Portuguese sun

Meet Jan-Willem van der Meijden, the Cultivation Specialist at Florensis. He started his career at Florensis Ethiopia (FET) in 2011 and later moved to Florensis Portugal in 2016. Being responsible for...

Read more