Behind the scenes at the production locations of Florensis

Did you always wanted to know what is going on at our production locations? General Managers Eddy Verbeek, Filipe Braga, Ronald Vijverberg and Olaf Kunert run our locations in Portugal, Kenya and Ethiopia with a focus on the well-being of the people of Florensis. With innovative and sustainable production methods the managers strive to create a qualitative and reliable product for you.

“Florensis grows, but in a steady and sustainable way, where people still know each other and want to invest in relationships.” - Olaf Kunert, General Manager Florensis Ethiopia

Can you introduce yourself?

My name is Olaf Kunert and I have been the General Manager at Florensis Ethiopia since May 2020.

What is your role at Florensis Ethiopia?

I manage one of the three farms that Florensis owns in Ethiopia. Ronald Vijverberg manages the other two farms in Abyssinia and Makeda. By training and managing mid-level management and staff, I want to reach the goal of making them more independent. At Florensis Ethiopia we produce a diverse assortment of plants, with more than 60 genetics and hundreds of different varieties. Our biggest crop is the Lavandula, but we also produce large cutting quantities of Dahlia, Osteopermum and Verbena for example My objective here is that we meet Florensis’ reliability goal of >97% rooting delivered with on time, with high quality.

What do you like about working at Florensis?

I like that I am part of a successful team and that our approach is always personal. I enjoy working for a family business where the communication lines to the board and with other managers are short and simple. Florensis grows, but in a steady and sustainable way, where people still know each other and want to invest in relationships.

Can you tell me more about one of your sustainability projects?

I am proud of our chemical reduction, that has even overachieved the ambitious goals set so far. For example, when we sterilize our crops two times a year, we now use a steaming technique instead of chemicals. Beneficial organisms fight pests. Nowadays the usage of these bugs is so successful and common that our plants can pass through border inspections easily. Another work in progress is the exchange of disposable plastic plant bags into reusable plant containers. These containers can be used for more than 10 years instead of the old ones, which we had to dispose of after two years.

Do you have a dream project?

We have a well within our company which is filled with water rich of minerals like sulphur. We use this water to heat our greenhouses. Moreover, we pass the water through our reverse osmosis filter system so that we can produce irrigation water. Our purified drinking water installation is serving our employees and next-door neighbour community. In the future I would like to have a more sustainable purpose for the brine that the irrigation system leaves behind. It would be great if we can transform the brine into a solid product which we could provide to farmers.

“The biggest project we are involved in now is the 'Kenyan Plastic Pact'. We are one of the few companies from the horticultural sector that is participating in this.” - Eddy Verbeek, General Manager Florensis Kenya

Can you introduce yourself?

I am Eddy Verbeek, General Manager at Florensis Kenya and in charge of keeping the show running for 15 years now.

What is your role at Florensis Kenya?

I keep in close contact with the different teams we have. 'Meet the plant Tours' are very important farm meetings, where we walk between the plants discussing issues of growing, planning and production. We send videos between the locations and have many online accessible data sources.

On the one hand, we are a production location, but at the same time we have the independence to go one step further in R&D. If we in Kenya think we can make a better product, one that is more sustainable and better in terms of costs, we are given the freedom to do so.

What do you like about working at Florensis?

Being social is in the DNA of Florensis. This can be seen in the way we treat people but also in the way we treat our environment. So it's about sustainability in the general sense of the word. We are a family run business but at the same time we also see our colleagues as family. That is the most important thing for me, besides continuing to innovate and accept new challenges. The complexity of the whole work process gives a powerful bond between colleagues, which is energizing.

Can you tell me more about one of your sustainability projects?

The biggest project we are involved in now is the ‘Kenyan Plastic Pact’, This has been set up together with the government and NGOs and all kinds of companies from different sectors so that we can jointly look at how we can reduce the plastic problem. We are one of the few companies from the horticultural sector that is participating in this. I am very proud of that.

Do you have a dream project?

Another big project is building a library and provide internet for all our employees who live in the village. We want to provide fun and educational books, for children and adults and the possibility that they can use the internet unlimitedly. This way we want to bring the total development of our employees to a higher level. This will also give them the opportunity to follow an online education and keep in touch with their families up country.

“Our goal was to reduce chemicals with 30% until 2025. We already achieved this goal in 2021 with integrated plant management. ” - Filipe Braga, General Manager Florensis Portugal

Can you introduce yourself?

Hi, I am Filipe Braga, General Manager at our Calibrachoa production location in Portugal since June 2013.

What is your role at Florensis Portugal?

My role as manager is to create and promote conditions, in which the people of our Portugal production location, feel part of a great international team and perform at their best. I am also responsible for the translation and execution of the mission, vision and goals of Florensis B.V. For example, this means I set directions, lead incentive projects, keep teams motivated and help HR to cope with changes. In Florensis Portugal we focus on the production of URC Calibrachoa, URC an RC of sedum sp, perennial seeds and tissues culture.

What do you like about working at Florensis?

I really like the international work environment. It challenges my capacities and competences and keeps me sharp. For me, completing a successful project is very rewarding on a personal and professional level. I like to be challenged and feel like working for Florensis is a continuous life challenge and learning process. With everything that I do I try to do an endoscopy, reflect on what went well and what could I have done to do it even better. So that I can take that into account, learn, improve, and grow when moving on to the next project, event, or activity.

Can you tell me more about one of your sustainability projects?

A project that I am especially proud of is the chemical use reduction. Our goal was to reduce chemicals with 30% until 2025. We already achieved this goal in 2021 with integrated plant management. This means we have gained competences, learned, and now apply technology which allows us to have a tied control of production factors. We created an optimal environment for our crops to grow healthier by using biologic pest control helpers such as: natural products, fungus, or bugs. These methods are both beneficial for our crops as for our nature. Keeping the environment and our greenhouse areas healthy and clean is our challenge and goal.

Do you have a dream project?

On the short term I would like to initiate a project of producing energy by solar power. This will be a real sustainable way of producing energy. The sustainability challenge of the future will bring us enormous opportunities to apply technology and our creativity to produce the highest and greatest project of our lives. We must think about how to produce even more sustainable without compromising our production objectives. It is also important for us to keep up with new cultivation methods and learn how to use new production techniques, in order to keep the quality high and meet market demand.

Meet and greet

Would you like to speak to Olaf, Eddy, Ronald and Filipe in person? Now is your chance. You can meet them at this years’ Flower Trials at Hendrik-Ido-Ambacht. Just like the rest of the Florensis team, they are excited to meet you there.

Latest news

Cooperation with Alpha Nurseries

In the world of plants, new ideas often come from working together and being creative. That is why Maarten Wouda, Sales Representative at Florensis took some groundbreaking initiatives in the plant market...

Read more

Visit our Spring Show 2024

After 2 years of development, we proudly present our latest value-added products within the market for biennials and spring-flowering perennials.

Read more

Helleborus Advent Star Event

Along with our top 10 Helleborus customers, we set up a trial to gain even more insight into the qualities of our Advent Star.

Read more

These Retail Solutions will help you take the next step in a sustainable assortment.

As growers and retailers, your want to offer customers gardening solutions that are both convenient and ecologically conscious.

Read more

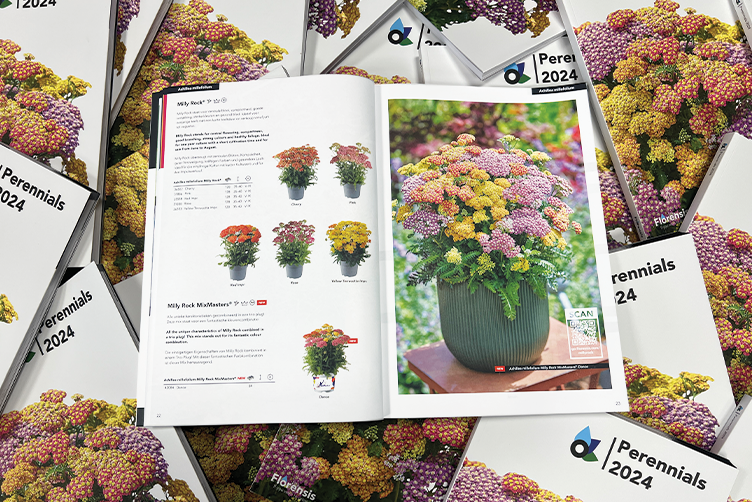

Check the Retail Solutions in our new Perennials Catalogue.

As with the Annuals catalogue, we thought about the environment with the Perennials catalogue by reducing the number of pages.

Read more

Why certifications and CO2 calculations can benefit you

As a customer, you want to know where your plants come from and how they are grown. Hans Goudswaard, responsible for Quality Assurance, considers transparency very important.

Read more