Why a healthy plant is more sustainable

The person who knows all about this is Ronald Geverinck, Project Manager at Florensis. He is the contact person for crop protection and informs our production locations about what is and isn't allowed and what can be used at their specific location (in the different countries).

In addition, he collaborates with various, mostly foreign, managers on projects that lie between production and R&D. These can be feasibility studies or technical projects, such as an installation to provide one of our Ethiopian locations with (an amount of) electricity 24/7, or a new fertilisation system that meets new requirements.

Other examples include developing a new transport box for unrooted cuttings or guiding trials to longer preserve unrooted cuttings. Sustainability often plays an important role in this. Ronald is also the coordinator of the internal Florensis Green Academy, where he collaborates with managers to provide training for anyone involved in ‘green business’, both domestically and abroad.

What is IPM?

To achieve the sustainable objectives, Florensis works according to the IPM principle (Integrated Pest Management). Measures are taken to prevent the plants from becoming infected by diseases and pests. Good hygiene is an absolute requirement for entering the greenhouses, prior to each new cultivation, but also while working with the plants. Providing an optimal climate in the greenhouses, fitting ventilation windows with insect screens, adopting a proper irrigation strategy and carrying out effective scouting in the crops are just some of the measures that are given considerable attention at all locations. Furthermore, biological crop protection agents that are hardly or not at all environmentally harmful are often used. Natural enemies of pests are also used to combat insects and even fungi. All these measures result in a substantial reduction in the amount of chemical products that still need to be used.

Green Academy

In collaboration with experts and training centres, training is provided to all colleagues who are more or less involved in our crop cultivation. The training programmes can be very broad in terms of subject matter, but ultimately all contribute to achieving our corporate objectives. Ronald ensures that the teachers who are approached match the Florensis employees' needs. This results in a well-coordinated programme for domestic and foreign colleagues.

What are you proud of?

"The knowledge level of middle and upper management has increased enormously at all locations over the years. Through training and sharing knowledge and experiences, it has been shown that we can still reduce the environmental impact on all produced young plants every year. This applies to all locations, without exception. A great common achievement. I'm really proud of that." Read more about our mission.

Challenges for the future

The consumer is becoming increasingly critical of chemical substances used in products. At the same time, fewer and fewer new crop protection products are being approved, and licenses for many existing products are not being renewed. As a result, the range of products that can be used is becoming increasingly limited. Ronald suggests that more attention needs to be focused on the front end of the process to prevent the need for chemical intervention. Developing plants that are more resilient to diseases and pests can contribute to this effort.

"However, we still know very little about how a plant is exactly structured in this regard. This is a major challenge, and we will need to conduct experiments to determine which substances we should or should not give the plant to make it 'happy' and thus more resilient and less susceptible to diseases and pests. This is how we work towards producing sustainable and high-quality plants for our customers."

Latest news

Cooperation with Alpha Nurseries

In the world of plants, new ideas often come from working together and being creative. That is why Maarten Wouda, Sales Representative at Florensis took some groundbreaking initiatives in the plant market...

Read more

Visit our Spring Show 2024

After 2 years of development, we proudly present our latest value-added products within the market for biennials and spring-flowering perennials.

Read more

Helleborus Advent Star Event

Along with our top 10 Helleborus customers, we set up a trial to gain even more insight into the qualities of our Advent Star.

Read more

These Retail Solutions will help you take the next step in a sustainable assortment.

As growers and retailers, your want to offer customers gardening solutions that are both convenient and ecologically conscious.

Read more

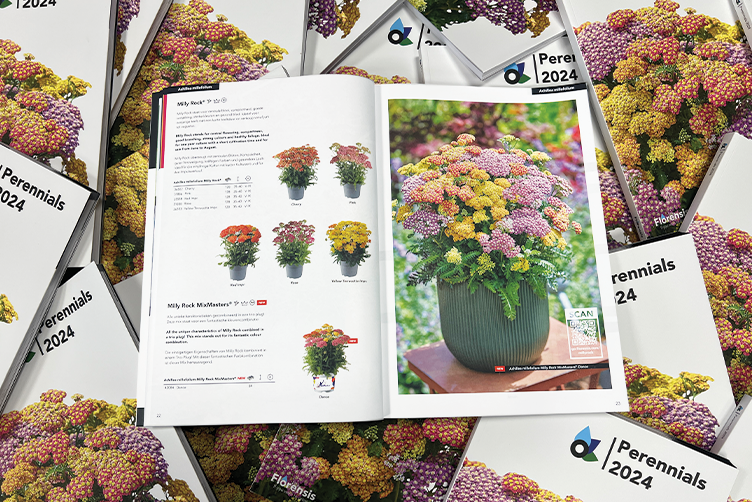

Check the Retail Solutions in our new Perennials Catalogue.

As with the Annuals catalogue, we thought about the environment with the Perennials catalogue by reducing the number of pages.

Read more

Why certifications and CO2 calculations can benefit you

As a customer, you want to know where your plants come from and how they are grown. Hans Goudswaard, responsible for Quality Assurance, considers transparency very important.

Read more